QUALIFIED SALES FORCE

OEM TRUSTED EQUIPMENT: LUCID | RIVIAN | VINFAST

Tru-Point One-Stop ADAS Calibration Solution

Tru-Point™ is the one-stop solution for all of your ADAS calibration needs.

Utilizing state-of-the-art camera technology, easy-to-place targets, and advanced software; Tru-Point™ quickly checks for ADAS related alignment issues so your technicians can perform accurate ADAS calibration with ease. Tru-Point™ advanced technology also eliminates the need for a completely level shop floor and removes the guesswork of manual measurements to allow your technicians the ability to accurately place ADAS targets with ease.

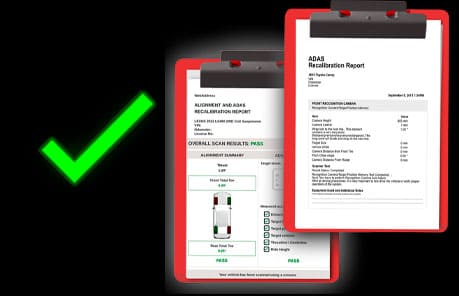

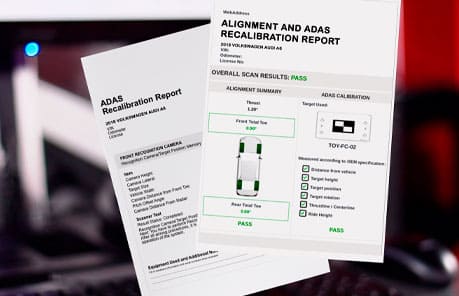

Calibrate and prove by combining Tru-Point™ with any ADAS-capable scan tool to complete calibration, and receive proof of calibration in an easy-to-read report. This is the ultimate in easy ADAS calibration, with the validation you and your customers are looking for.

CHECK

Tru-Point™ uses highly advanced camera technology to create a 3D image of a vehicle and verify alignment in under a minute. This helps your technicians waste less time performing ADAS calibration for vehicles that do not meet OEM alignment specifications.

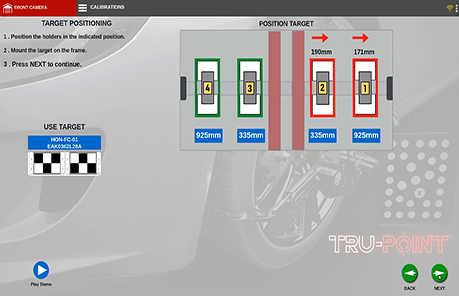

PLACE

Streamline the process of placing targets at precise OEM-required locations with Tru-Point™ technology. Think you need tape measures and a level floor to get the job done? Tru-Point™ makes this process seamless and guides this process automatically without the need for lasers, tape measures, or plumb bobs.

CALIBRATE

Designed to make life just a little bit easier, Tru-Point™ works with any ADAS-capable scan tool to complete the calibration process. Worried about constantly changing requirements and servicing newer vehicles? Tru-Point™ offers Manual Mode for Premium subscribers to set up and calibrate vehicles not yet in the database.

PROVE

Once Tru-Point™ validates the alignment of the vehicle, placement of the targets, and compliance with OEM specifications; it will generate an easy-to-use report that clearly shows compliance. This ensures that you are putting a safe vehicle back on the road and provides proof to your customer that will put their mind at rest.

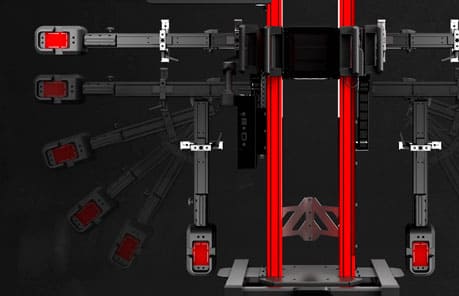

BUILD YOUR OWN SYSTEM

Shop with confidence for calibration targets and the most current data for the vehicle makes and models you work with, ensuring that all your calibrations are done accurately and efficiently.

DOWNLOAD OUR AUGMENTED REALITY APP TO SEE TRU-POINT IN YOUR SHOP:

Our custom app will allow you to explore Tru-Point™ in a whole new way – with both 3D and realistic Augmented Reality experience.

Features

OEM COMPLIANT

Perform a precise recalibration according to the OEM specifications.

PRECISE TARGET PLACEMENT

A simple color-coded system allows you to easily identify the exact location for target placement going from red to green.

VALIDATION REPORT

Tru-Point™ validates the alignment of the vehicle, placement of the targets, and compliance with OEM specifications.

THRUST LINE / CENTERLINE

DISTANCE FROM VEHICLE

TARGET ROTATION

TARGET POSITION

TARGET HEIGHT

RIDE HEIGHT

ALIGNMENT

STEERING ANGLE

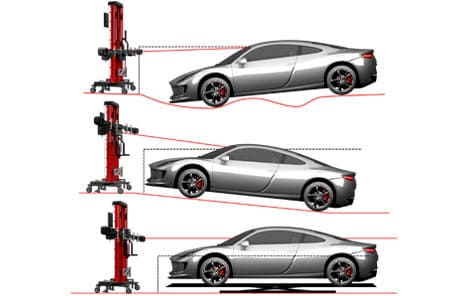

FLOOR COMPENSATION (LEVEL FLOOR NOT REQUIRED)

While most systems function by referencing the height of the vehicle from the shop floor, our system measures the height of the targets from the tire contact patch of all four wheels, allowing for the vehicle to be calibrated anywhere in the shop; even on an alignment rack.

VIDEO: SEE IT IN ACTION

ADDITIONAL FEATURES

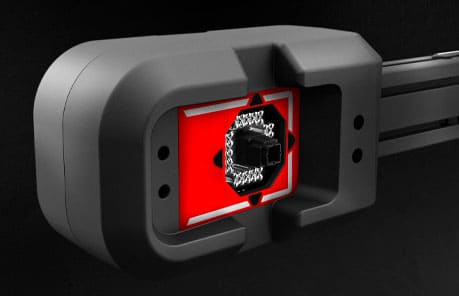

CAMERA SYSTEM

3D modeling capabilities allow the system to replace lasers and tape measures.

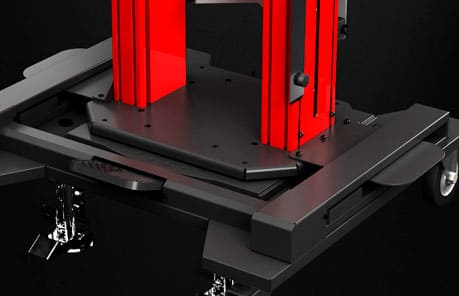

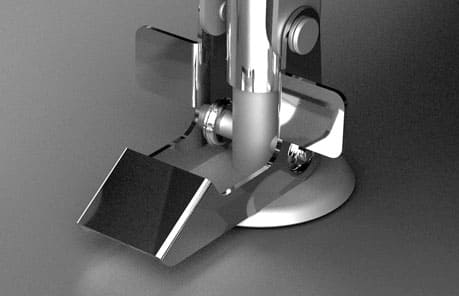

PRECISION BEAM ADJUSTMENT

Integrated with a turntable allowing you to easily perform the fine adjustment on the targets without extra effort.

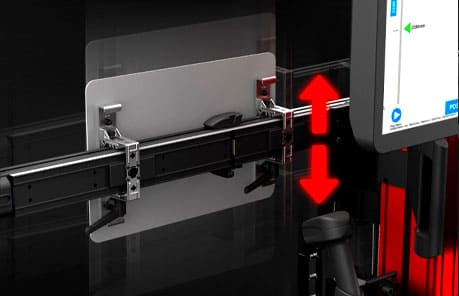

HEIGHT ADJUST

Release the brake on the right handle and freely move the beam up and down for target height.

FOLDING ARMS

Provides you with a more compact system that’s easy to store and delivers greater mobility.

FOOT PEDAL

Allows you to move the beam back and forth without having to move the entire system.

LOCKS

Push down on the locking mechanism, to provide extra stabilization and anchor the base to the floor.

TESTIMONIALS

TECH SPECS

Part Number

EESE505B

EESE505A (Includes Deluxe Kit & Target Cart)

Tire Size (AC400)

19”-39” | 48-99cm

Dimensions

82″x113″x30″ | 208x287x76cm- Extended

82″x53″x30″ | 208x135x76cm – Folded

Weight

376 lbs. | 170.5 kg – Equipment

512 lbs. | 232.2 kg – Shipping

Power requirements

100-240V

Display

24” TFT

ACCESSORIES

STANDARD

OPTIONAL